DRYERS

Dryer are most commonly used in many type of industrial processing applications, key purpose of industrial dryers are to eliminate or remove moisture, water and other solvents from the material under processing. Dryers should be carefully designed so that it does not to changes or affects the physical, chemical or biological properties of material. Since, dryers are built in various types of shapes with different specification; selection of right dryer is the key for effective processing.

Our experts are having experience of many years in helping various types of industries with designing of various types of custom build drying solution. We help the client in selection of Dryers, by understanding the prerequisite for quality and moisture content of the ultimate dried product.

We design dryers that can suit to various critical applications across industries such are chemical, pharmaceutical, food, wood, paper production, ceramics and many more. Our specialties are in designing & manufacturing of various types of specialized and generalized Industrial dryers those can be easily used in various industrial applications.

APPLICATIONS OF DRYERS

• Dairy • Food • Chemicals • Coffee • Wood • Starch • Ceramic

TYPES OF DRYERS

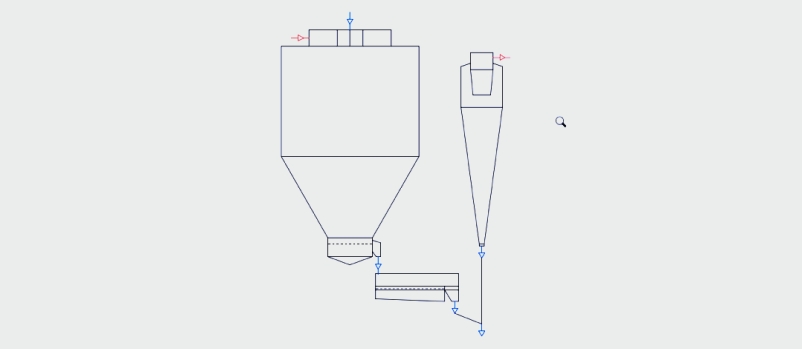

1. Spray Dryers :

With firm commitment towards quality, we are manufacturing and supplying a wide range of Spray Dryers. These dryers are used in various industries for drying and evaporating water from thermally-sensitive materials such as foods and pharmaceuticals. Our specialty dryers are sturdy in construction and are highly efficient. These dryers are demanded in the drying plants for dairy, food, chemical and pharmaceutical industries.

Features

• Controlled noise level

• Compact Design

• Unmatched Quality

• Less Maintenance

• Durability

• Easy operations

2. Flash Dryers :

Flash Dryers are used for drying of wet cakes which are sensitive to heat. There are different variations of flash dryers available depending upon the need to disperse the wet cake or pastes.

Features

• Less drying time hence less labor handling and quick production

• Less electricity load

• Energy consumption saving

• Fuel consumption saving

• The environmental conditions remain clean

3. Fluid Bed Dryer :

In this dryer, wet material is fed on its shaking perforated steel bed through which the drying air flows. As the material passes along the dryer it gradually loses moisture until the target dryness is achieved using hot air. After achieving desired level of moisture content, the product cooled by passing it thru cooling section of the dryer.

Features

• Uniform Drying at low temperature

• On line sampling Port

• Minimum handling / more Hygienic

• Top Spray Granulation

• Provision for Explosion relief

4. Agitated Thin Film Dryer :

It is used to produce free flowing powder from slurry/solution type feed and widely implemented in pharmaceutical, chemical & food industries. These are used in situations where the solutions cannot be handled by conventional dryers/evaporators. It is a jacketed shell precision machined from inside and a rotor having blades that maintain a close clearance from the shell.

Features

• Continuous, fully enclosed processing

• Short residence time

• Low residual volatile in final powder

• Superior mixing efficiency

• High Reliability

• Low Maintenance

5. Rotary Dryer :

We offer dryers, which are used for drying easily breakable and dispersible wet powders and cakes. These are equipped with a rotating drum along with an angle lifting blades which lift the feed as the drum rotates and blows it in the stream of hot air flowing through the drum.

Features

• Simplicity in design

• Sturdy construction

• Adaptability to fluctuating feed rates & moisture contents of products

• Possibility of very large through-puts

6. Steam Tube Dryer :

Steam tube dryers utilize conduction for heat transfer. They are indirect heating dryers where the product does not come in contact with the heating medium (steam). Steam tube dryers have a long history of reliable service, drying a wide range of products.

Features

• Low temperature, indirect drying

• High thermal efficiency

• Exceptional product quality

• Minimal process air flow

• Relatively low emissions

• Proven dependability

• Simple operation

• Low maintenance

7. Paddle Dryer :

The wet feed is continuously agitated by the heated rotating blades, thus exposing new areas to heating surfaces. This results in the moisture boiling off and rendering the material to dry to the required degree. Mostly, these dryers are used for heating, drying, pasteurization, cooling, crystallizing and drying of pastes, cakes, powders, and granules.

Features

• Low running cost

• Continuous production machine without human touch

• Ideal for solvent recovery

• Suitable for Crystalline material

• Compact design

• Initial particle size is maintained