EVAPORATORS

Owing to our expertise in this domain, we offer our clients an exclusive range of Industrial Evaporator. These Evaporators are fabricated as per the Customer’s process parameters utilizing the best grade components and other basic materials. We hold immense expertise in manufacturing and supplying quality proven range of Evaporators. These machines evaporate the unwanted volume of water or any other kind of solvent from the solution. These evaporators are manufactured under the supervision of our expert professionals using quality tested raw material that had been sourced from certified vendors. Our dedicated stainless steel fabrication shop ensure contamination free manufacturing process.

Features

• Easy installation • Smooth performance • Low power consumption • Effective working • Low Maintenance • Hassle free installation • High efficiency • Compact design

APPLICATIONS OF EVAPORATOR

• Dairy • Coffee • Fruit Juice Concentration • Sugar Cane juice Concentration • Herbal & Phytochemical • Agro Chemical • Pharmaceutical Bulk Drug • Brine Evaporation, • Salt Recovery • Dye Intermediates, • Distillery Wastewater Effluent • Sodium Sulphate Crystallization, • Solvent recovery • Chemicals • Starch and its Derivatives • Effluent Concentration, • Concentration and disposal of high TDS streams and Concentration of RO rejects.

TYPES OF EVAPORATOR

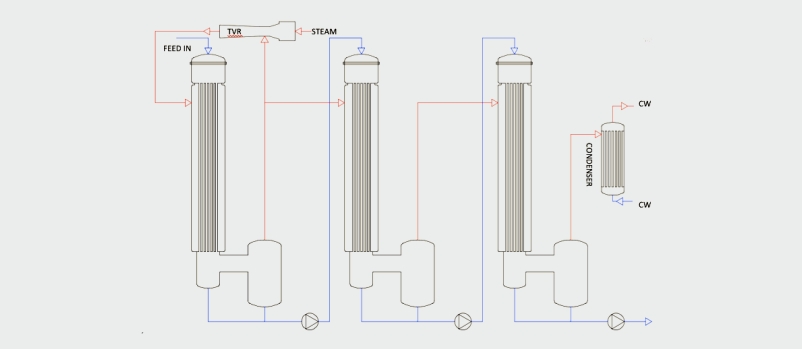

1. Falling Film Evaporator :

These evaporators are used to evaporate the unwanted volume of water or any other kind of solvent from solution. In order to ensure their quality, these are manufactured at our developed infrastructure using superior quality input. These evaporators are ideal for low temperature applications and for high thermal efficiency.

Features

• Large evaporation capacities

• Low Scaling and fouling

• Low fixed and operating costs

• Optimum heat transfer area

• Good heat transfer coefficients at all temperature gradients

• Easy accessibility and compact layout

• Low temperature operation

• Best suited for clear, foaming and corrosive solution

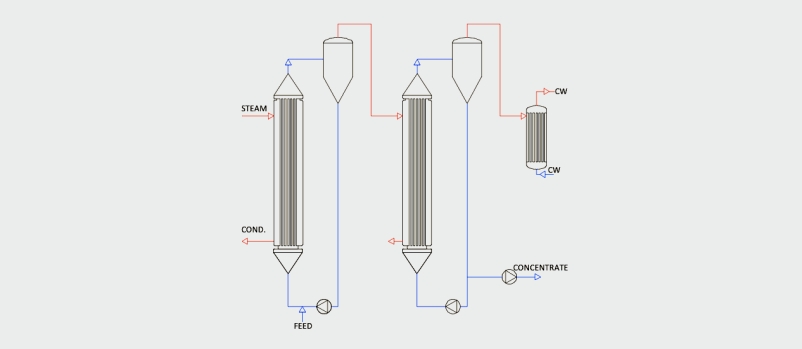

2. Forced Circulation Evaporators :

With rich industry experience, we are presenting our clients a quality range of Forced Circulation Evaporators. These products facilitate long lasting performance and are manufactured at our highly developed infrastructure using high grade raw material. Our evaporators are suitable for processing crystallizing duties, thermally degradable materials concentration and inversely soluble materials concentration. They are widely used in various industries for their rigid construction, accurate dimension and resistance to abrasion and corrosion.

Features

• Robust construction

• High durability

• Easy to install

• Solvent recovery

• Compact Design

• Easy operations

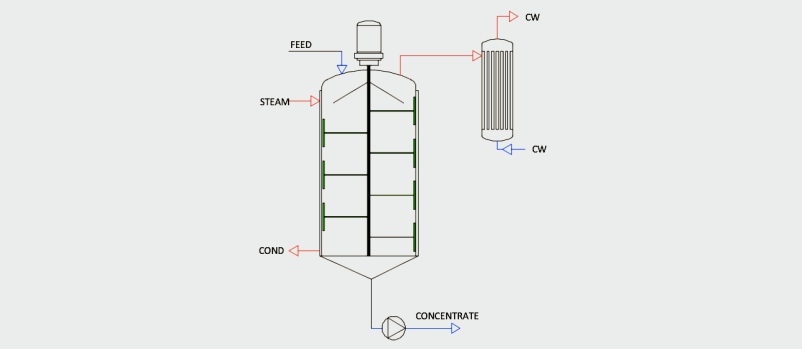

3. Agitated Thin Film Evaporators :

We manufacture these machines using superior raw material procured from our most trusted and certified vendors at our developed infrastructure units. These evaporators are used to separate a mixture of liquids having different boiling points and to increase the concentration of liquids. Our offered products are highly resistant to abrasion and corrosion and facilitate a flawless performance during their service life. Moreover, our clients can avail these at very nominal prices.

Features

• Low utility consumption

• High capacity

• Reduced costs

• Easy to install

• Solvent recovery

• Compact Design

• Easy operations

4. Combination of Falling & Forced Circulation Evaporator :

Depending upon the process conditions, the type of Falling Film Evaporator is selected. Normally combination of stages is required based on the process. The concentration of dilute solution to the saturated solution is most suitable for this system.

Features

• Rapid liquid movement due to high heat transfer coefficient.

• Salting, scaling and fouling are not possible due to forced circulation.

• Suitable for thermo labile substances.

• Suitable for the viscous preparation.

5. Natural Circulation rising film Evaporator :

This system operates by natural circulation thermo-siphon action and thereby eliminates the need for large pumping systems, alternately it can operate in a single pass. The upward force of vapor produced by the boiling liquid pushes the rising liquid into a thin film with a great amount of turbulence. Such hydraulics offer an advantage for processing more viscous products and those which would foul a more quiescent falling film design.

Features

• Simple to operate

• Eliminates large circulation pumps

• Compact configurations

• High heat transfer coefficients reduce capital cost