BIN WASH SYSTEM

The Automatic Bin Washing Station is the best solution for washing, drying, and cooling of IBC in Food, Pharma and Chemical Industries.

Construction

Bin wash system consists of :

• Enclousure for bin placement.

• Suitable High pressure pump is provided for circulation of cleaning liquid at various stages.

• Stand alone air handling system is provided for heating, cooling and drying of bin.

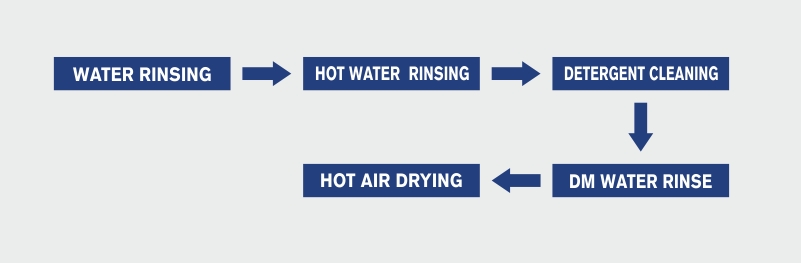

Working

• IBC is positioned inside the washing chamber.

• Doors are closed.

• Actuate the wash cycle

• Wash cycle is PLC controlled with protocol print out.

• Completion of wash cycle is indicated by Alarm.

• Washed bins are removed from the other side of wash chamber.

Applications

Washing if IBC

Capacity

• 100 Ltrs to 2000 Ltrs Bin

• 10 bins per Hours based on product charactristic

Advantages

• Effective cleaning of IBC with optimum utilisation of water.

• High pressure operation and specially-designed solid stream nozzle that increase impact ensure through cleaning.

• Nozzles rotate in multiple axes and provide complete coverage of the entire tank.

• External Air motor drives rotational speed; cycle times can be changed without changing the liquid pressure.

• Long service life – CE-rated air motor is positioned outside the tank away from harmful caustics.

Salient Features & Options

• Max. Temp. : 90°

• Max. Working Pressure : 0 – 200 Bar

• Max. Flow: 0 – 60 LPM

• Cleaning Nozzles: 2 Nos.

• Material : Stainless Steel

• Seals : EPDM