MATERIAL / POWDER HANDLING

1. TIPPER : Lifter and Tilter Unit

The Tipper Unit is a standalone unit allowing minimum manpower with cGMP concept for Lifting and Tilting of the FBD bowl.

Construction

Tipper consists of following :

• Hydraulic lifting Device

• Product container holding Hopper

• Tilting arrangement

• Hydraulic power pack

Working

• Product container is placed below the inverted hopper.

• Product container is clamped to the Inverted hopper.

• The whole assembly is lifted and rotated upside down so that inverted hopper receives the granulated material from Product container.

• Material collected in the hopper is ready for discharge in to the next collection point like: Mill, IBC, etc.

Applications

Dust free transfer of granulated product from FDB to next work station.

Capacity

Available from range 60 kg – 600 kg can be extended as per client’s requirement.

Advantages

• Tipper is Easy to operate and clean.

• Totally closed operation to avoid dusting.

• Connect with granulator for continuous discharge.

• Tipper is Easy to clamp with fluid bed dryer bowl.

Salient Features & Options

• Ideal for faster operation with minimum dust generation.

• Tilting head integral with lifting head and housed on the yoke with horse shoe shaped SS lifting cradle.

• Tilting degree of the cone provided by double action hydraulic cylinder through specially designed rack and pinion assembly.

• Hydraulic Power Pack operated through custom built panel with pushbutton station for Raising / Lowering & Tilting with limit switches for controlling the UP / DOWN movement.

• MOC SS 304/3I6.

2. IBC Bin

Now a days Bin are most acceptable standard for intermediate storage, Blending etc, specially for containment application.

Construction

IBC Bin consists of :

• Rectangular OR Circular body with inverted Pyramid shaped or Conical shaped bottom.

• These bins are mounted on Frame.

• Frame have Fork lift handling.

• Top has Manway / Loading.

• Bottom has discharge with Butterfly Valve.

Applications

• Intermidiate Storage of Powder.

• Transfer of powder to RMG, Tablet Press, etc.

• Collection of Powder from Mill.

• Blending of Containt thru Bin Blender / Cage Blender.

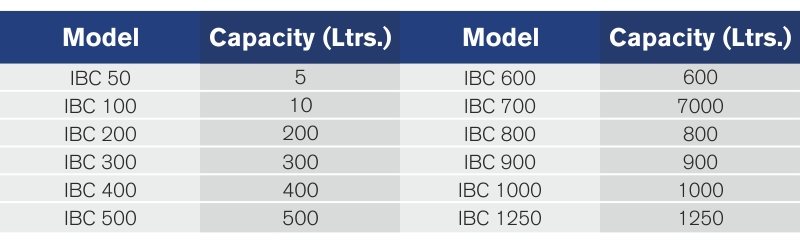

Capacity : 5 Lit to 1250 Lit.

Advantages

• Most suitable for containment application.

Product Range

Salient Features & Options

• All parts are made of s.s 304/ s.s 316 grade.

• Easey to clean.

• Stacking feature can be provi.

• 5 Lit. to 1250 Lit. (can be designed as per users specification)